A small guide to conventional cylindrical grinding machines

In the age of digital transformation and automation technologies, it would be easy to assume that manual, conventional cylindrical grinding machines will be replaced by CNC-controlled machines. However, despite the increasing use of CNC technology, conventional cylindrical grinding machines still assert themselves as indispensable tools in many areas of metalworking.

These are conventional cylindrical grinding machines

Conventional cylindrical grinding machines are designed for high-precision machining of cylindrical workpieces. They are mainly used in the automotive industry, aerospace engineering, mechanical engineering and medical technology, where they are used to grind workpieces with the highest precision. In contrast to CNC cylindrical grinding machines, the control and fine adjustment of the grinding processes is done manually, which puts the focus on the ability and expertise of the user.

The machines enable the extremely high precision required for components that require dimensional accuracy in the micrometer range . This means that they are able to correct the smallest deviations in surfaces and diameters.

Construction of a conventional cylindrical grinding machine

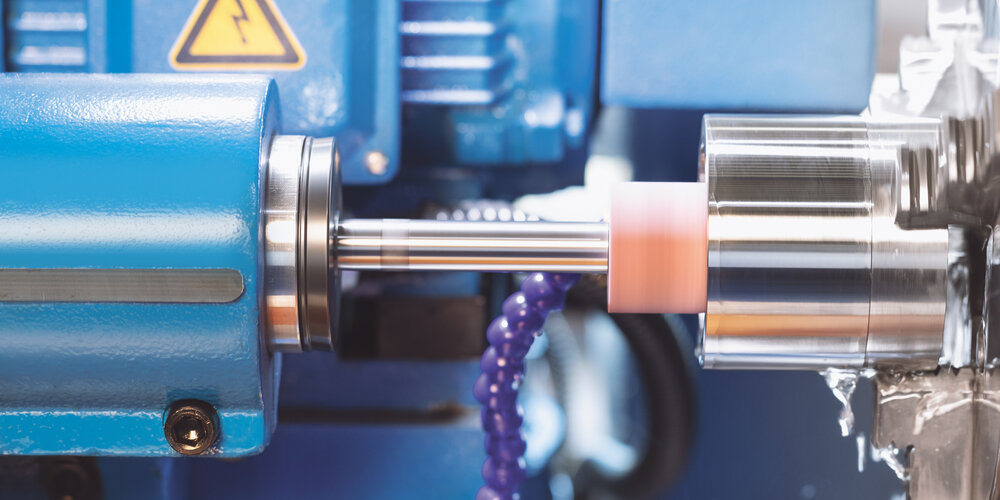

A cylindrical grinding machine consists of several essential components that enable precise grinding of cylindrical workpieces. At the center is the grinding spindle, which drives the grinding wheel and sets it in precise rotation. Opposite is the workpiece headstock, which holds the workpiece either between centers or in a clamping device and also allows it to rotate. These components are mounted on the machine bed, which ensures stability and minimizes vibrations. The tailstock provides additional support for the workpiece, especially for longer workpieces, while the support guides the grinding head precisely along the workpiece axis to produce uniform surfaces. In addition, there are often coolant systems that remove heat and chips during grinding.

Thanks to the swiveling internal grinding device, the KNUTH cylindrical grinding machines are essentially converted into internal cylindrical grinding machines whenever it is necessary to machine internal surfaces or holes in short workpieces. This offers the advantage that no separate internal cylindrical grinding machine needs to be purchased, which significantly increases the efficiency and flexibility of the machining process.

Conventional cylindrical grinding machines vs. CNC cylindrical grinding machines

The main difference between conventional cylindrical grinding machines and CNC cylindrical grinding machines is the way in which the grinding process is controlled. With conventional cylindrical grinding machines, the grinding process is controlled manually by an experienced operator. These machines offer a high level of flexibility when machining individual parts or small series, as adjustments can be made directly and without complex programming. They are ideal for workshops that require quick changes or precise adjustments.

CNC cylindrical grinding machines, on the other hand, are computerized and automate the entire process. They are particularly efficient in large batch production because they are programmable and ensure consistent quality for each workpiece. CNC machines also offer greater repetition and process stability, but require more preparation time due to programming and are more expensive to purchase. While conventional machines benefit from the user's craftsmanship, CNC machines offer faster and standardized production.

What you should consider when buying a conventional cylindrical grinding machine

Here are the most important factors to consider when choosing the right machine for your needs:

Grinding Length and Center Width

The grinding length and center distances are crucial parameters because they determine which workpiece diameters and lengths can be machined on the machine. The grinding length indicates the maximum length of the workpiece that can be ground. The center distance describes the distance between the centers that support the workpiece during processing. If you regularly machine long workpieces such as shafts or axles, you should make sure that the grinding length is sufficiently dimensioned.

Grinding Diameter

In addition to the length of the workpiece, the maximum grinding diameter also plays a key role: it indicates the maximum diameter a workpiece can have in order to be able to machine it on the machine. Depending on the application, you must ensure that the machine covers the desired diameter range. In precision engineering, smaller diameters are often machined, while in the automotive industry or in mechanical engineering, larger workpieces with a greater weight are typical.

Ergonomics and User-Friendliness

Operating a conventional cylindrical grinding machine requires manual skills, so the machine should have a user-friendly and ergonomic design. This makes it easier for the operator to adjust and control the machine during the grinding process. Make sure the controls are easily accessible, the displays are clear and the working height is ergonomic. The KNUTH USA team will be happy to advise you on this topic and train your team.

What to Know about Operation and Maintenance?

Conventional cylindrical grinding machines are characterized by their durability and comparatively low operating costs. But here too, regular maintenance is a must to ensure the precision of the machine in the long term. This includes:

- Lubricate the guides and bearings.

- Regularly change the grinding wheels depending on wear.

- Clean the machine to remove chips and dust that could affect precision.

Another advantage of these machines is that they can be retrofitted in many cases. Older models can be equipped with digital measuring technology, which significantly improves the accuracy and control of the grinding process. The integration of modern coolant systems can also increase the efficiency of the machine.

An indispensable tool for the future of metalworking

Although CNC machines dominate many areas of industrial production, the conventional cylindrical grinding machine remains invaluable for specific applications. Its flexibility, accuracy and cost-effectiveness make it particularly attractive for workshops and manufacturing environments where one-off pieces or small series are required. Conventional machines will therefore continue to have a firm place in modern metalworking.

For users looking for high precision, flexibility and manageable operating costs, conventional cylindrical grinding machines remain a proven choice. They combine traditional craftsmanship with the ability to machine individual and complex components - with a level of precision that humans can control through manual skill.

Buy conventional cylindrical grinding machines from KNUTH

Are you looking for the right grinding machine for you? Our range offers the right solution for various applications. Many of our products are immediately available. Simply request the price and all the details via our website and let our experienced team advise you. We will be happy to help you find the ideal model for your needs - request by email or telephone .

From installation to maintenance of your machine

Our service does not stop after your machine has been delivered. We support you during installation and commissioning and offer training so that you and your team can use the full potential of your new machine. Our technical support and repair service are always there for you and our network of service partners ensures quick on-site assistance. Thanks to our well-stocked spare parts warehouse, components for older machines are also quickly available. This way we ensure that your cylindrical grinding machines work reliably and remain in operation for a long time.